Home > News & Blog > How to Choose the Best Glass Tempering Furnace Manufacturers?

Selecting the right glass tempering furnace manufacturer is a critical step for any business in the glass processing industry. Whether you produce flat glass for architecture, automotive, or interior applications, the efficiency, precision, and durability of your tempering machines directly affect product quality and energy consumption. This guide will help you understand what to look for and how to evaluate the furnaces features that make a real difference.

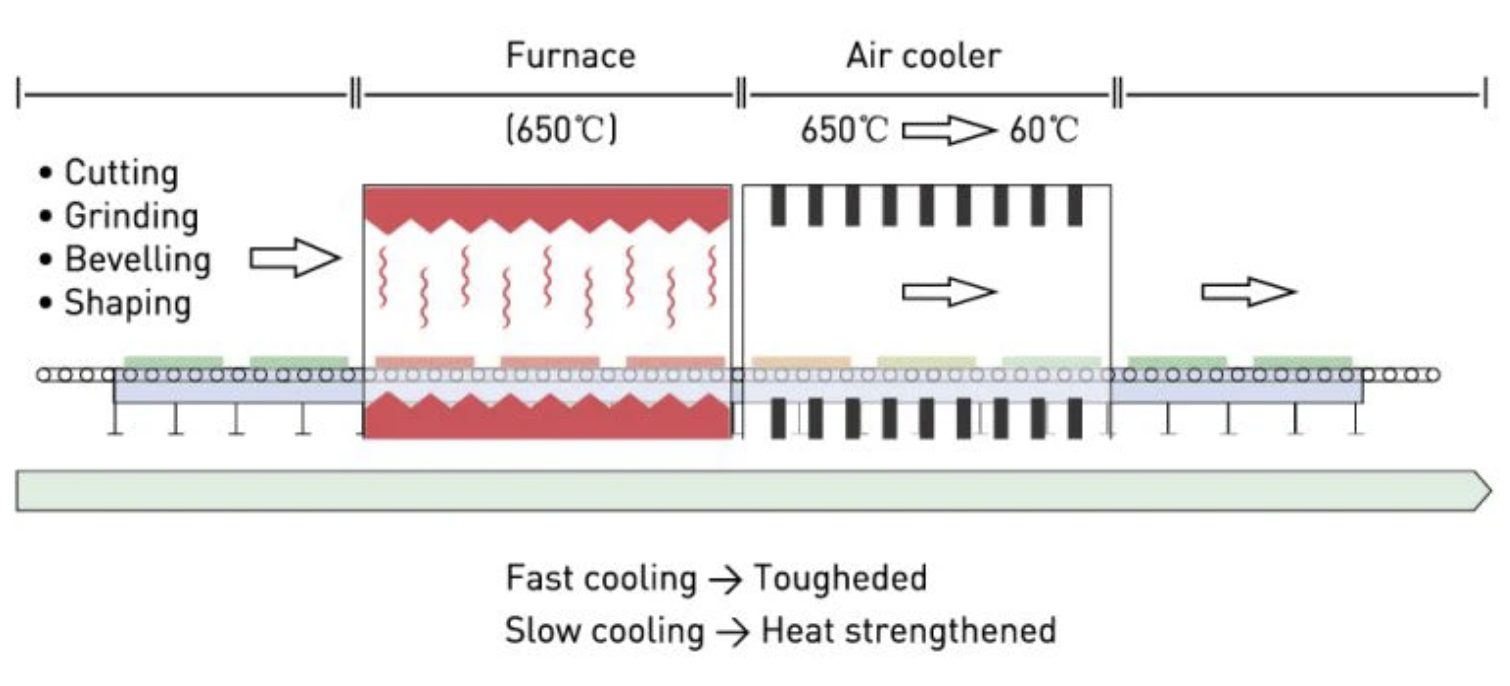

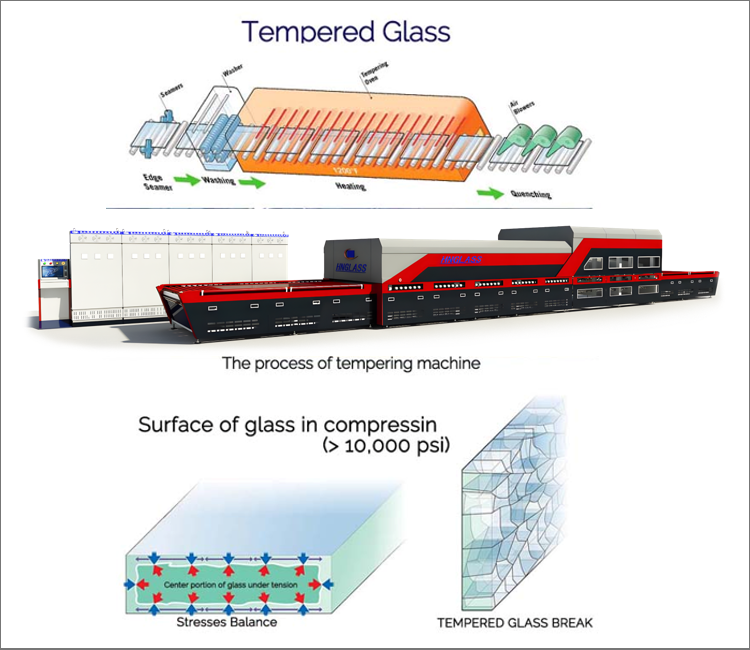

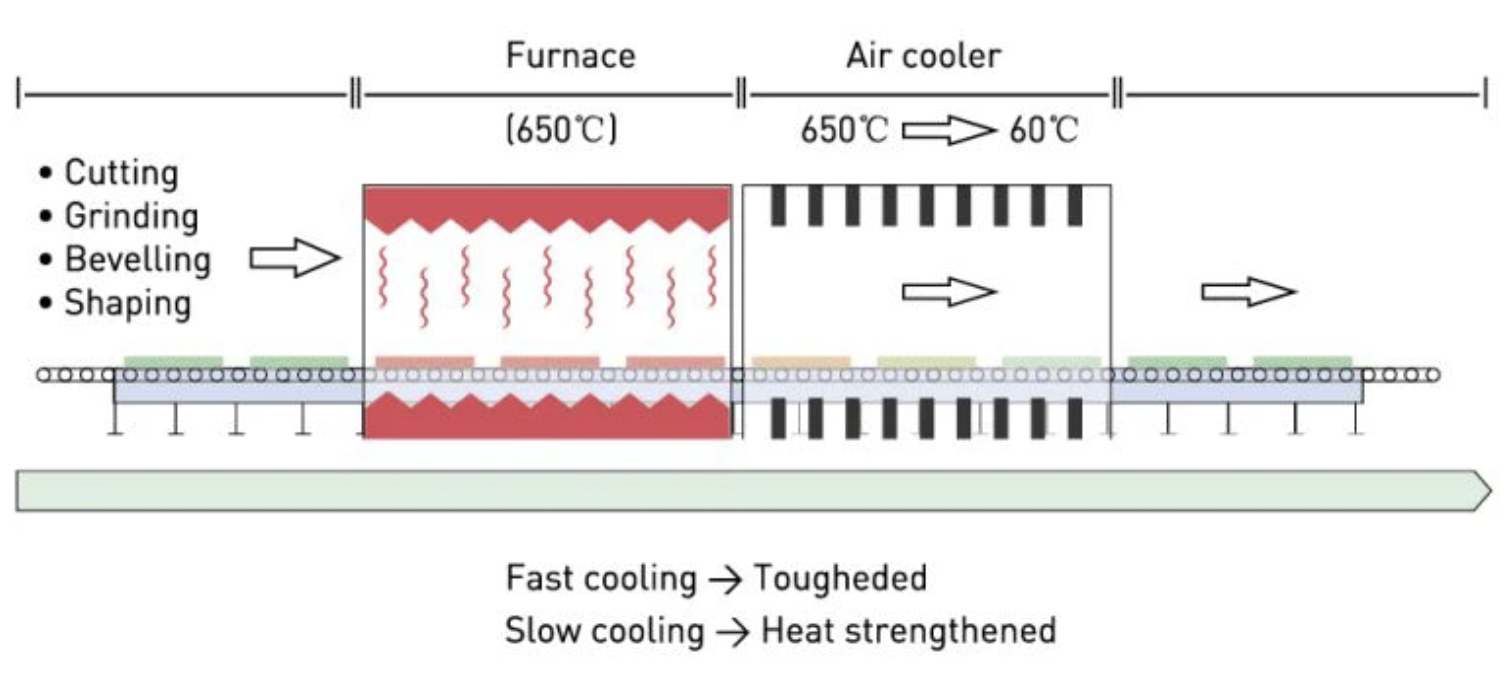

The tempering process involves heating the glass to a high temperature (usually around 650°C) and then rapidly cooling it with high pressure air jets. This controlled heating and cooling cycle increases the glass strength by four to five times compared to ordinary glass.

Modern tempering furnaces use advanced control systems to ensure uniform temperature distribution and stable quick cooling performance. This is especially important for flat glass, where uneven heating can cause optical distortion or surface stress.

When comparing flat glass tempering furnaces, consider the following furnaces features that impact productivity and quality:

A high-quality tempering furnace not only produces superior glass but also reduces downtime and maintenance.

To choose the best glass tempering furnace manufacturers, focus on the following factors:

Working with a trusted tempering furnace manufacturer means gaining access to stable equipment performance, efficient heating and cooling, and precise control systems. The result is flat glass with consistent quality, smooth surface finish, and long-term durability. In addition, modern tempering machines support energy savings through optimized airflow and quick cooling efficiency.

Q1: What is the main purpose of glass tempering?

The goal of the tempering process is to make glass stronger and safer by using heating and cooling cycles that create balanced internal stresses.

Q2: How does a glass tempering furnace work?

A tempering furnace heats glass evenly and then uses high pressure air to rapidly cool it, resulting in toughened glass with higher impact resistance.

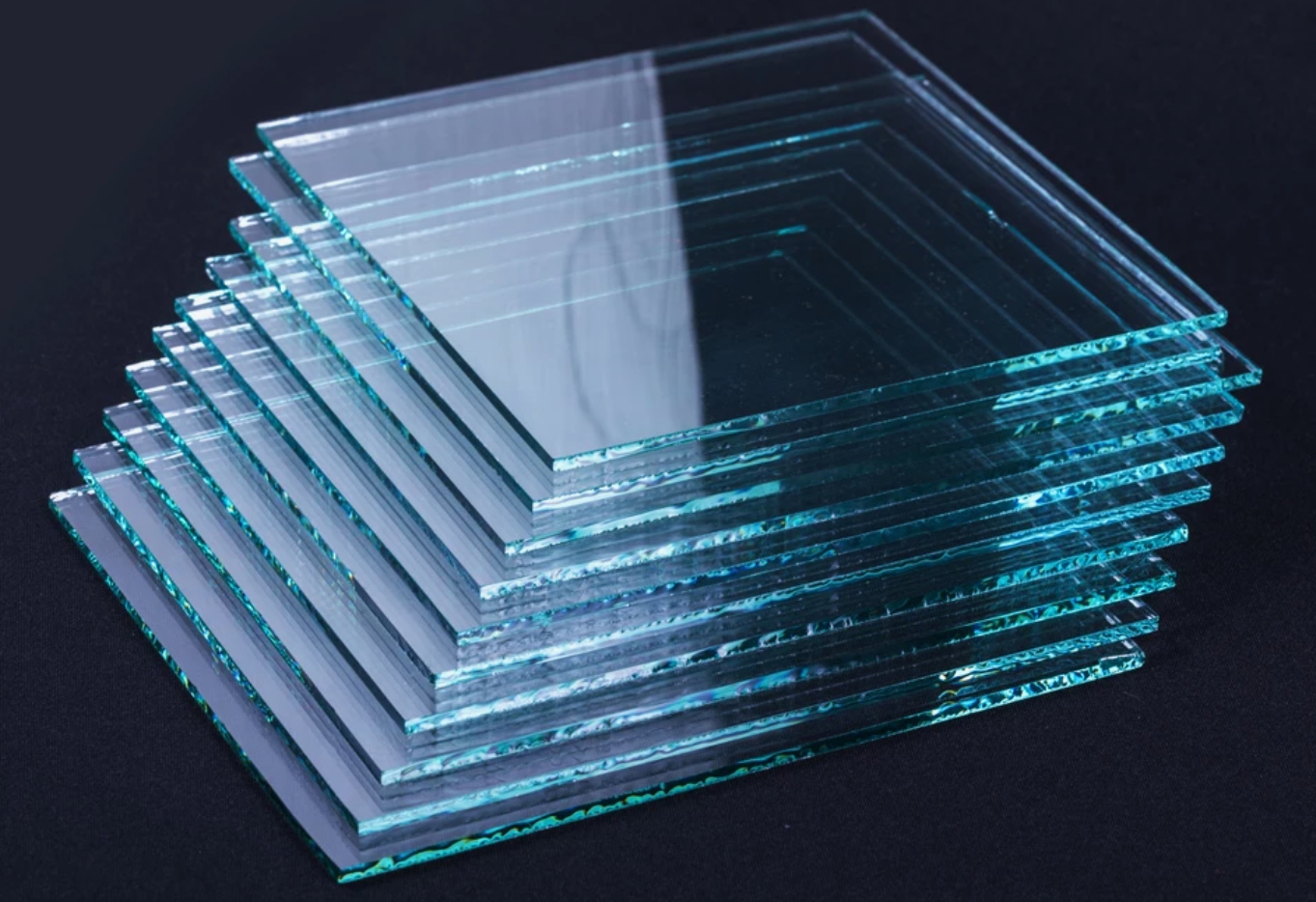

Q3: What type of glass can be tempered?

Typically, flat glass is tempered for use in windows, doors, facades, and automotive applications. Special furnaces can handle Low-E or coated glass.

Q4: What should I look for in the best tempering furnace manufacturers?

Choose manufacturers that provide high-quality machines, efficient control systems, reliable quick cooling performance, and strong technical support.

Q5: How can I ensure consistent quality in the tempering process?

Use furnaces with advanced heating the glass technology, uniform airflow for rapidly cooling, and automated control systems for precise operation.

Choosing the right glass tempering furnace manufacturer is essential to achieving consistent, high-quality results in your glass processing operations. Look for proven technology, energy efficiency, and strong after-sales support. A reliable flat glass tempering furnace with a robust control system and optimized heating and cooling performance ensures long-term productivity and superior product quality.